The Art and Science of Toy Testing and Quality Control

Introduction

Quality control is an essential aspect of the toy industry. With the

importance of ensuring the safety and enjoyment of children, toy testing

has become both an art and a science. Manufacturers and retailers invest

significant resources to ensure that their toys meet stringent quality

standards. In this article, we will explore the fascinating world of toy

testing and quality control, uncovering the key features and processes

involved.

The Importance of Toy Testing

Toy testing serves as a crucial step in the manufacturing process.

Ensuring that toys are safe, durable, and meet regulatory requirements is

not only a legal obligation but also a moral responsibility. Here are

some of the key reasons why toy testing is of utmost importance:

-

Safety

The safety of children is paramount. Toy testing helps identify and

mitigate potential risks such as choking hazards, sharp edges, or

toxic substances. -

Durability

Toys must withstand the playful nature of children. Rigorous testing

ensures that toys can withstand various forces and usage patterns,

thereby reducing the likelihood of accidents or breakages during play. -

Compliance

Toy manufacturers must comply with strict regulatory standards. Testing

verifies if toys meet requirements set by organizations such as the

Consumer Product Safety Commission (CPSC) or the European Union’s EN71

standard. -

Brand Reputation

A strong brand reputation is built on trust. Thorough toy testing

demonstrates a commitment to quality and safety, enhancing a brand’s

image and credibility among consumers and retail partners.

The Toy Testing Process

Toy testing involves a comprehensive process that evaluates various aspects

of a toy’s safety, functionality, and quality. Though the specifics may

vary depending on the toy’s nature, here are the general steps involved:

-

Design Concept Assessment

At the early stages of toy development, a conceptual assessment is

conducted to evaluate potential risks and safety concerns associated

with the toy’s design. This phase helps identify and rectify any issues

before proceeding further. -

Raw Material Testing

Testing the materials used in toys is essential to ensure compliance

with safety regulations. This involves analyzing the chemical composition

and physical properties of materials to identify potential hazards. -

Product Functionality Testing

This phase focuses on evaluating a toy’s functionality and performance.

It includes tests such as checking battery life, movement capabilities,

and any special features or functions. -

Safety Testing

Safety testing encompasses a range of assessments, including mechanical

and physical properties tests, flammability tests, and toxicological

evaluations. These tests ensure that the toy meets safety standards and

does not pose any immediate or long-term risks to children. -

Age Grading Verification

Toys are often labeled with recommended age ranges. Age grading

verification ensures that toys are appropriate for the intended age

group, taking into consideration factors such as small parts, choking

hazards, or complex features that could pose risks to younger children. -

Packaging and Labeling Assessment

The packaging of a toy plays a vital role in providing necessary

information to consumers. Assessing packaging and labeling helps

ensure accurate age recommendations, proper instructions, and warning

labels, enhancing consumer awareness and safety.

Toys and Quality Control Features

Quality control features are integral to ensuring well-crafted and safe

toys. Manufacturers focus on implementing the following features during

the production and testing phases:

-

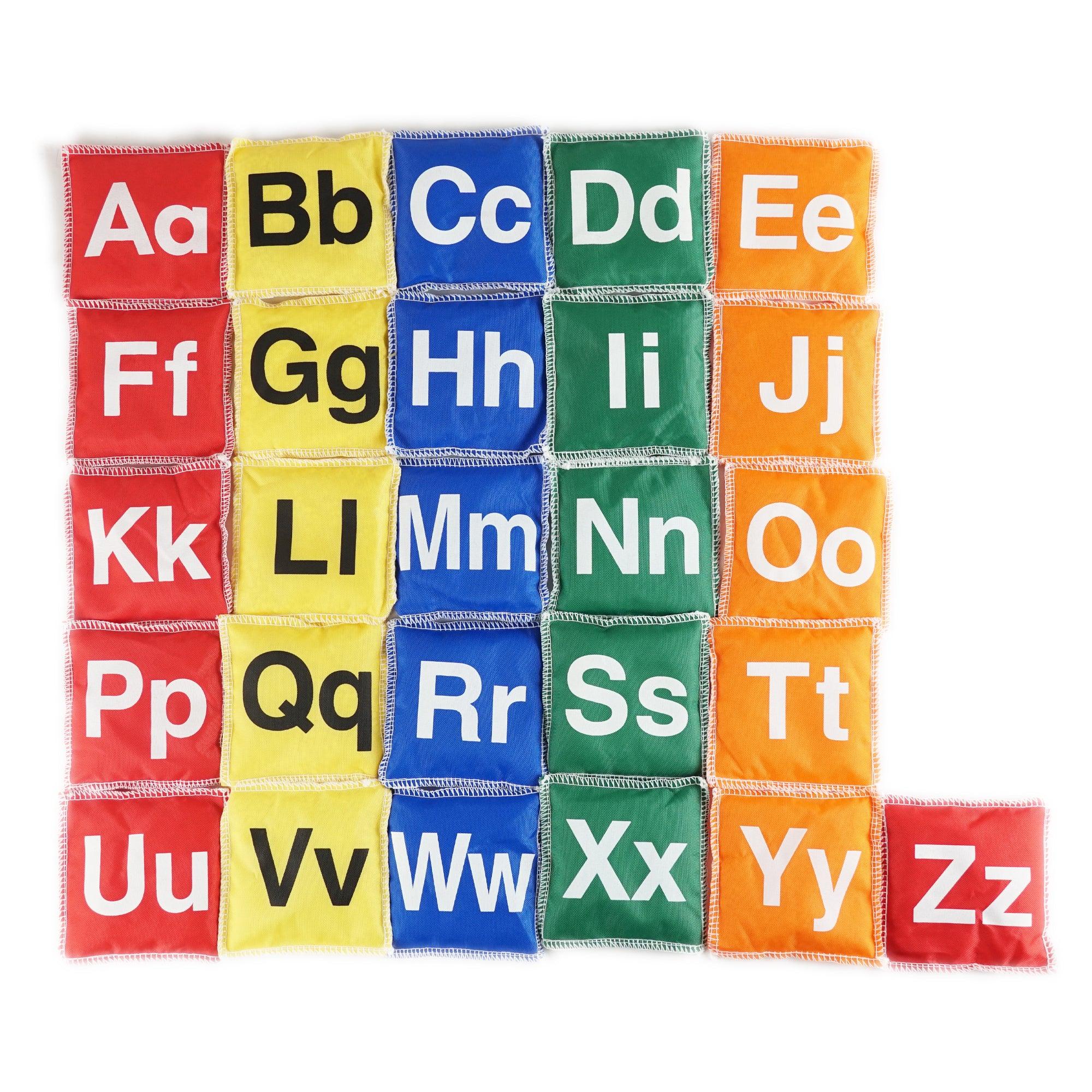

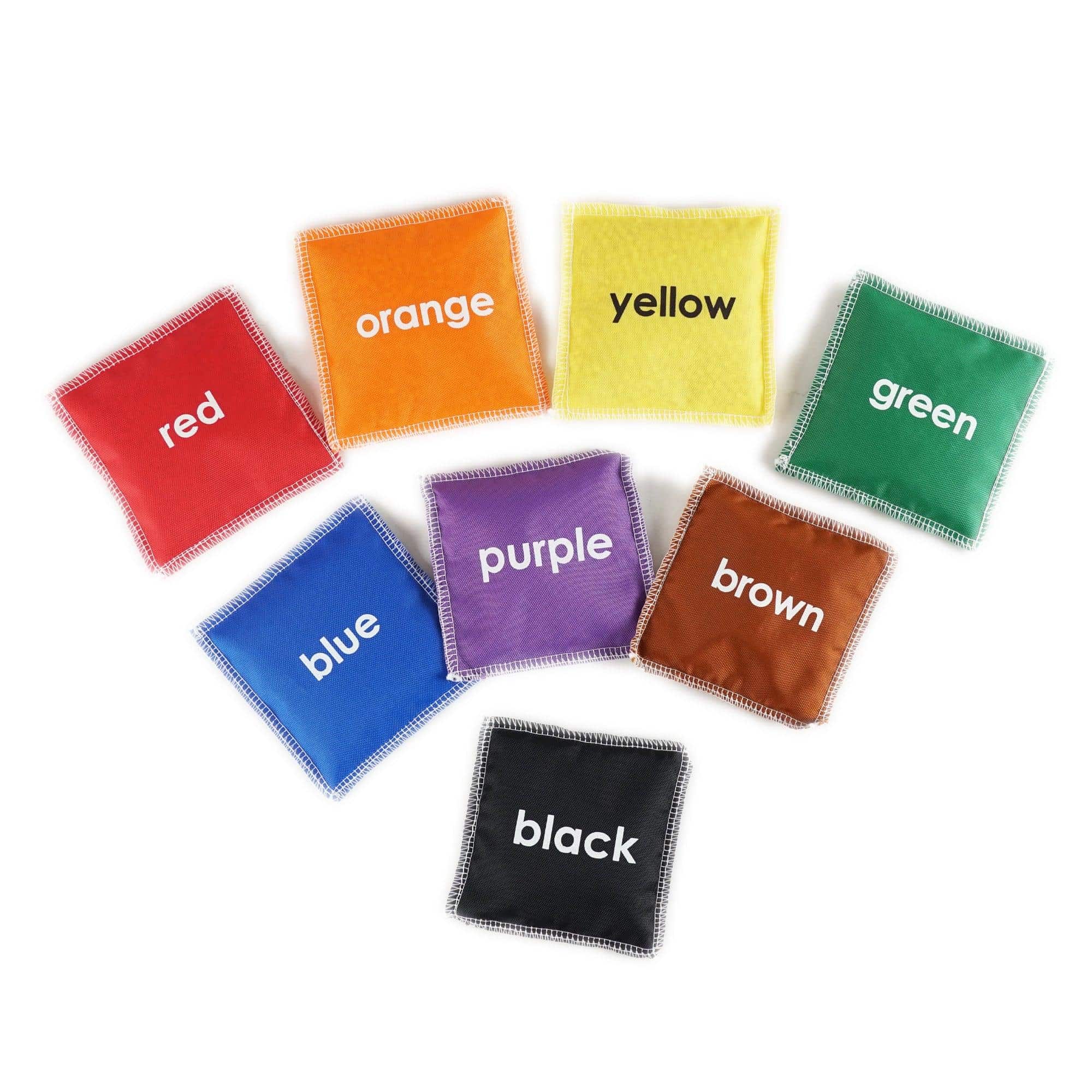

Durable Materials

Toys made from durable materials, such as high-quality plastics or

reinforced fabrics, enhance longevity and reduce the risk of

breakages or accidents during play. -

Non-Toxic Components

Ensuring that toys are free from harmful substances, such as lead or

phthalates, is crucial. Quality control verifies compliance with

regulatory guidelines to guarantee the safety of children. -

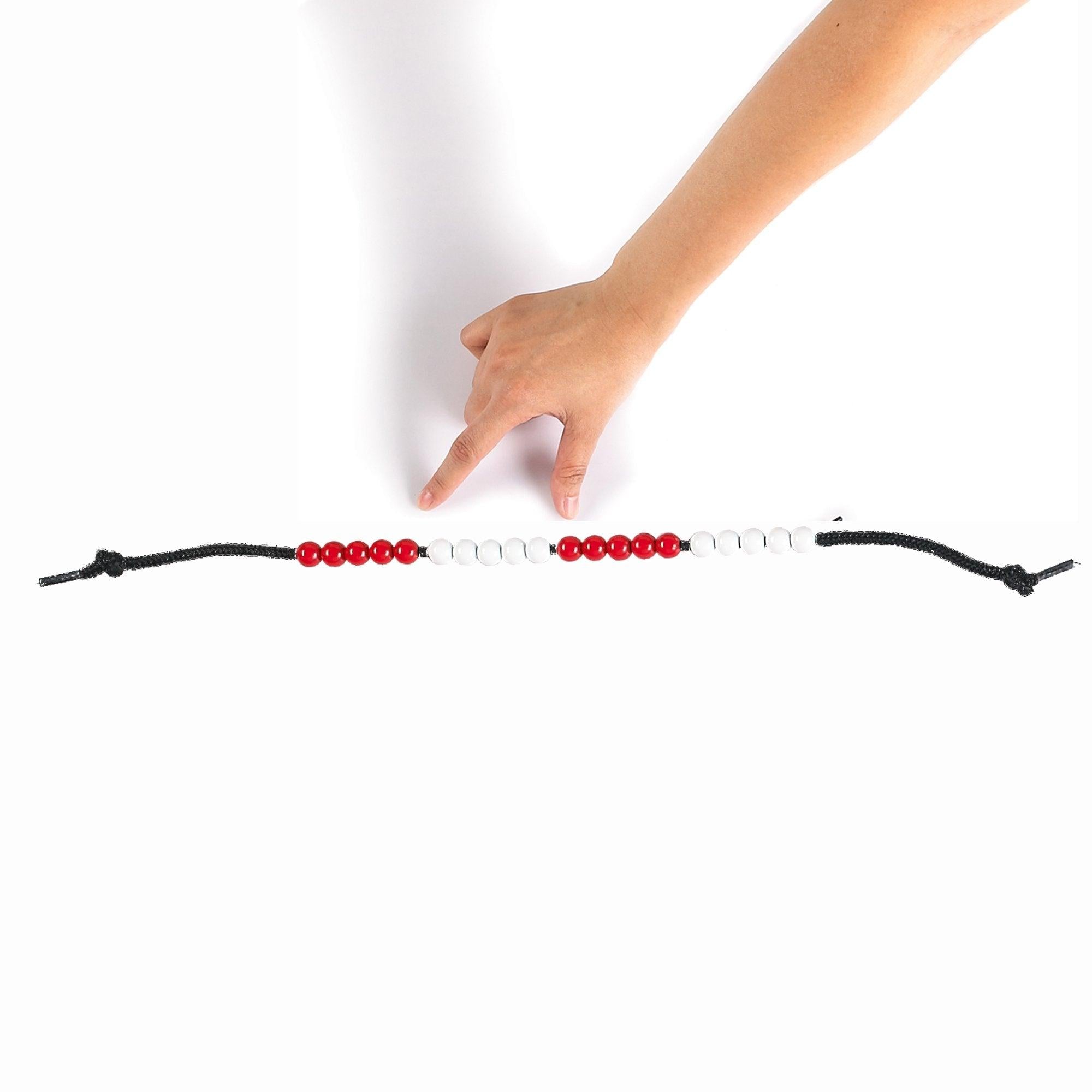

Secure Fastenings

Toys with small components or detachable parts undergo rigorous testing

to ensure that fastenings are secure. This helps prevent choking hazards

and minimizes the risk of accidental swallowing or injuries. -

Design Optimization

Quality control focuses on refining toy design to maximize safety and

appeal. Rounded edges, smooth surfaces, and age-appropriate features

contribute to a toy’s overall quality and reduce potential risks. -

Quality Assurance Checks

Thorough quality assurance checks are conducted throughout the toy

manufacturing process. These checks encompass inspections at various

stages, including material sourcing, assembly, and final product

assessment, guaranteeing consistent quality and adherence to standards.

Conclusion

The art and science of toy testing and quality control play a pivotal role

in ensuring safe and enjoyable play experiences for children. Toy testing

not only satisfies regulatory requirements but also helps build trust,

protect brand reputation, and ultimately bring smiles to children’s faces.

By adhering to stringent quality control measures and embracing innovative

testing methodologies, the toy industry upholds the highest standards,

enriching the lives of young ones worldwide.